When it comes to rigging, the safety of both equipment and personnel is paramount. An essential component in rigging toolkits is the bow shackles. These sturdy, U-shaped connectors are invaluable for linking chains, wires, and ropes in various applications. However, to ensure the utmost safety and effectiveness, it’s crucial to understand how to use the equipment properly. Explore five key aspects of their usage, from selecting the right type to inspecting and maintaining them regularly.

Choosing the Right Type

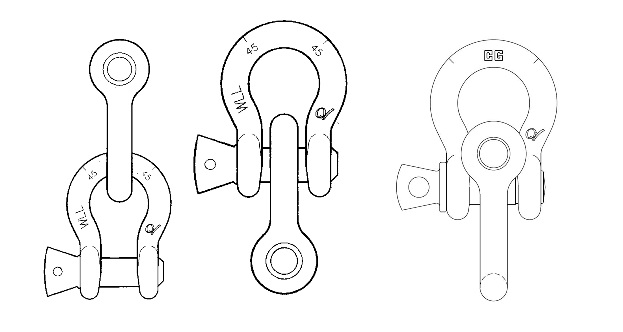

The first step in safe rigging with this equipment is selecting the appropriate type for your needs. These pieces of equipment come in various designs, including screw-pin and bolt-type ones. Screw-pin ones are commonly used for non-permanent applications, while bolt-type ones are preferred for long-term or heavy-duty usage. Match the equipment’s Working Load Limit (WLL) with the load you intend to lift or secure. Always err on caution and choose equipment with a higher WLL than your load requires.

Inspecting Your Equipment

Before each use, it’s crucial to inspect your bow for any signs of wear, damage, or deformities. Start by examining the equipment’s body and pin for cracks, bends, or corrosion. If you notice any defects, no matter how minor they may seem, do not use the piece. Instead, replace it with a new, undamaged one. Additionally, check that the pin is securely tightened and that the equipment’s markings are still legible. These markings provide essential information about its specifications, including its WLL.

Properly Attaching the Equipment

To ensure safety, it’s essential to correctly attach the bow shackles to the load and the anchor point. Begin by threading the pin through the eye, ensuring it goes through both holes in its body. Next, secure the pin by tightening it with a wrench. Use a cotter pin or safety bolt, if applicable, to prevent the pin from accidentally loosening during operation. Always attach the equipment so that the load is aligned with its axis to minimise side-loading, which can reduce the strength.

Consideration for Angles and Loading

When rigging with these things, it’s essential to consider the angle between the legs of the equipment and the direction of the load. As the angle increases, the effective WLL of the equipment decreases. To calculate the reduced WLL for angled loads, you can use a load angle factor chart or formula provided by the manufacturer. Remember that using equipment with a higher WLL or employing multiple pieces in a “sling” configuration can help compensate for reduced capacity due to angle and loading considerations.

Safe Rigging Practices

To ensure the safety of all workers in rigging operations, it’s crucial to adhere to safe rigging practices. This includes wearing proper personal protective equipment, providing adequate training to all workers, and strictly following manufacturer guidelines for equipment usage. Additionally, always avoid shock loading, which can significantly reduce the lifespan of the equipment. Shock loads can occur when a load is suddenly applied or released, causing extreme stress on the equipment and other rigging components.

Conclusion

Bow shackles are indispensable tools in rigging, providing a secure connection for lifting and securing heavy loads. To ensure their safe and effective usage, it’s vital to choose the right type of equipment, inspect it regularly, and follow proper attachment procedures. Understanding the impact of angles and loading on the equipment’s capacity and adhering to safe rigging practices will further enhance safety in your operations. Remember, safety should always come first when working with these pieces of equipment, and any compromised equipment should be replaced promptly to prevent accidents and ensure smooth rigging operations.